4 machining centres

Maximum traverse path:

- X = 800 mm,

- Y = 800 mm,

- Z = 550 mm.

Photo : Hermle AG - www.hermle.de

4 machining centres

Maximum traverse path:

Photo : Hermle AG - www.hermle.de

3 machining centres

Maximum traverse path:

1 machining centre

Maximum traverse path:

1 machining centre dedicated for graphite milling

Maximum traverse path:

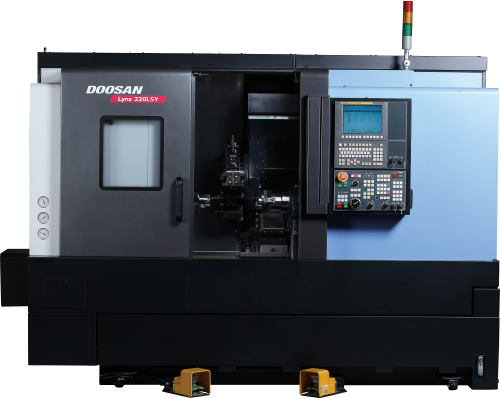

1 lathe machine equipped with Y axis

Maximum machining scope:

CNC horizontal lathes of various machining capabilities equipped with bar feeders

Maximum machining scope:

4 automatic cutting and machining machines with various machining options equipped with material feeders.

Maximum machining scope:

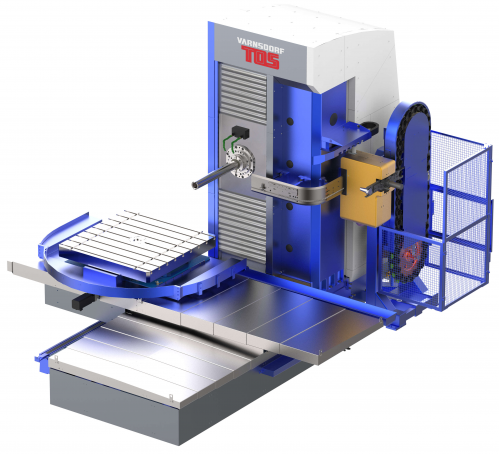

The machine is designed for quick and efficient preparation of metal parts for machines and equipments.

Operations performed:

Our main machinery park is complemented by a number of conventional machines operated by qualified staff. We also have manual welding stations.

| Machining | Scope of machining , mm | Part weight, kg | Accuracy, mm | Remarks |

|---|---|---|---|---|

| Rough turning | Ø 1600 | 1000 | +/- 0,5 | |

| H 1000 | ||||

| Final turning | Ø 910 | 1000 | +/- 0.1 | |

| L 4000 | ||||

| Rough milling |

800x2000x800

|

2000

|

+/- 0,5

|

|

| Final milling |

800x2000x500

|

2000

|

+/- 0,1

|

|

| Drilling and boring | 1600x1400 | 8000 | +/- 0,1 | Boring up to Ø 800 mm |

| Surface grinding |

1500 x 1200

|

600

|

+/- 0,01

|

|

|

Shafts and cones grinding

|

Ø 550 |

1000

|

+/- 0,01

|

The apex angle up to 25 deg

|

| L 4000 | ||||

|

Cylindrical and conical holes grinding

|

Ø 6-200 |

1000

|

+/- 0,01

|

The apex angle up to 60 deg

|

| L 200 | ||||

| Bars cutting | Ø 240 | 2000 | +/- 1,0 |

We constantly cooperate with local companies providing high quality services in the field: