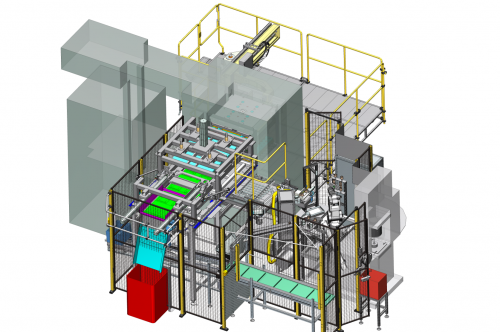

Operations: Production of a rubber-metal product by injection moulding, calibration of the product, 100% visual inspection and packaging.

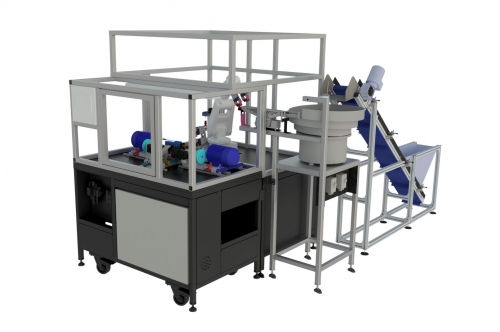

Main elements:

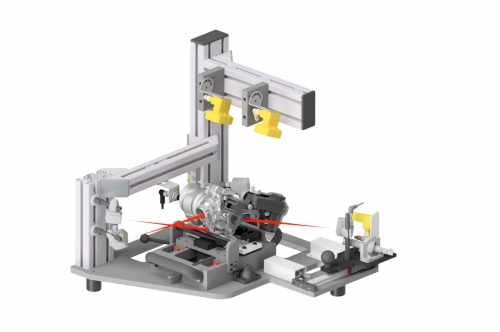

- Manipulator with loading plate for metal parts

- Product unloading station and injection channel

- Product receiving feeder system

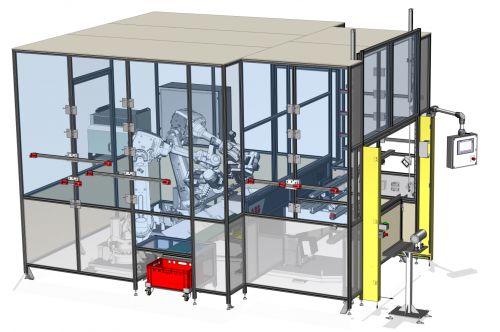

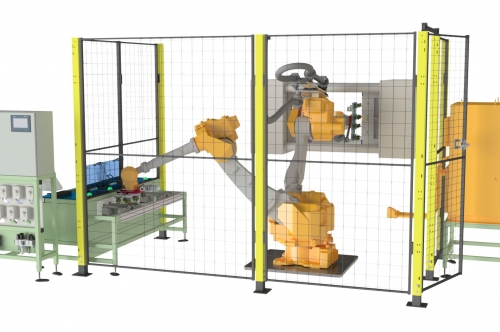

- Robot with equipment installed

- Control systems for flash, product diameter, short shots, marking and OK/NOK segregation

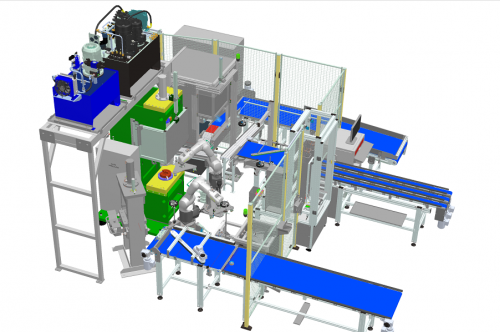

- Packaging and transport of packaging

A line designed to work with an injection moulding machine and a hydraulic press.

Overall dimensions of the stand L x W x H: 7100 x 7250 x 3000

Operations: The loading of the metal parts is followed by injection and vulcanisation of the rubber mix. Once the mould is opened, the injection and overflow channels are automatically removed and the vulcanised rubber-metal products are discharged. Using a conveyor, the products are moved to the calibration and marking station. After visual inspection, the products are packaged and transported to the collection point.